Extensive D2C shop & PIM project with GRIMME

- Relaunched the GRIMME spare parts shop in the UK using Spryker

- Central data management with Pimcore

- Spare Parts Finder for agricultural machinery

- Centralized machine compatibility checking for items

Download Case Study GRIMME

Assignment

GRIMME, a family-owned company founded in 1861 and based in Damme, Germany, is a leading international manufacturer of high-quality and innovative agricultural machinery. Our project with GRIMME involved two key objectives: Firstly, we utilized the Spryker eCommerce system to revamp GRIMME’s spare parts shop for the UK market. In addition, we introduced the Pimcore system to centralize data management and processing.

Challenge

One of the main challenges of this project was mapping the intricate structure of agricultural machinery down to individual spare parts. This functionality allows customers to navigate through the assemblies and subassemblies of a machine to find the compatible spare parts they need. To achieve this, we needed to process and integrate large amounts of data across various systems. A significant focus was on integrating the Pimcore and Spryker systems, along with external apps and third-party systems, to ensure efficient data synchronization.

Solution

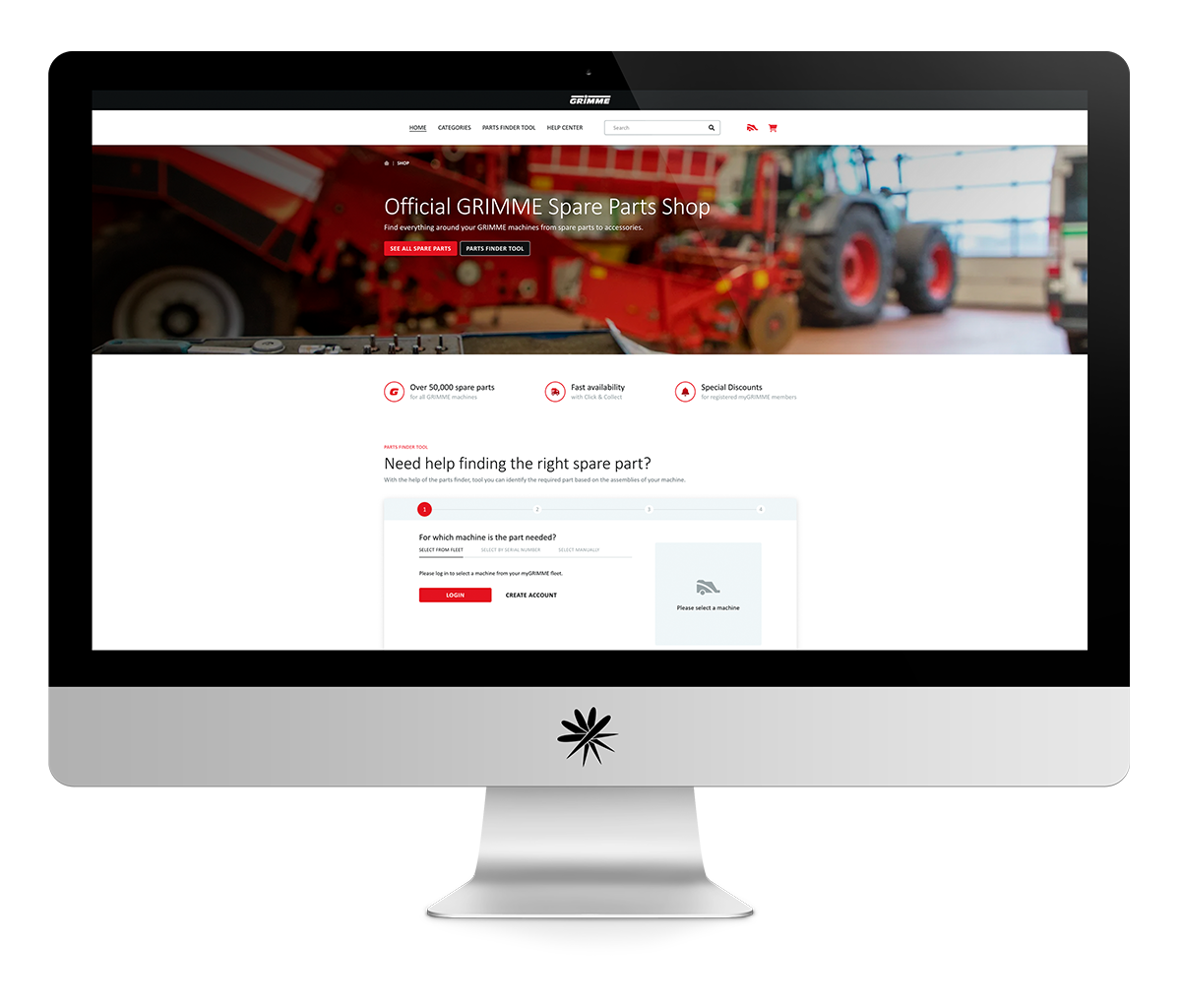

Spryker PaaS+

Due to the limitations of the existing shop, the relaunch was based on the Spryker PaaS+ cloud solution. Spryker PaaS+ is an optimally coordinated platform environment for developing, operating and managing the system. This offers GRIMME several advantages: firstly, it utilizes the full flexibility of the Spryker Commerce OS, while at the same time eliminating the need to worry about infrastructure maintenance, system updates, or patches. Lastly, the PaaS solution also ensures excellent performance and easy scalability. With the launch of the new UK online shop, GRIMME is taking the first step towards D2C sales, allowing end customers to purchase spare parts directly from GRIMME. Additionally, several features were implemented to enhance the customer experience in GRIMME’s shop.

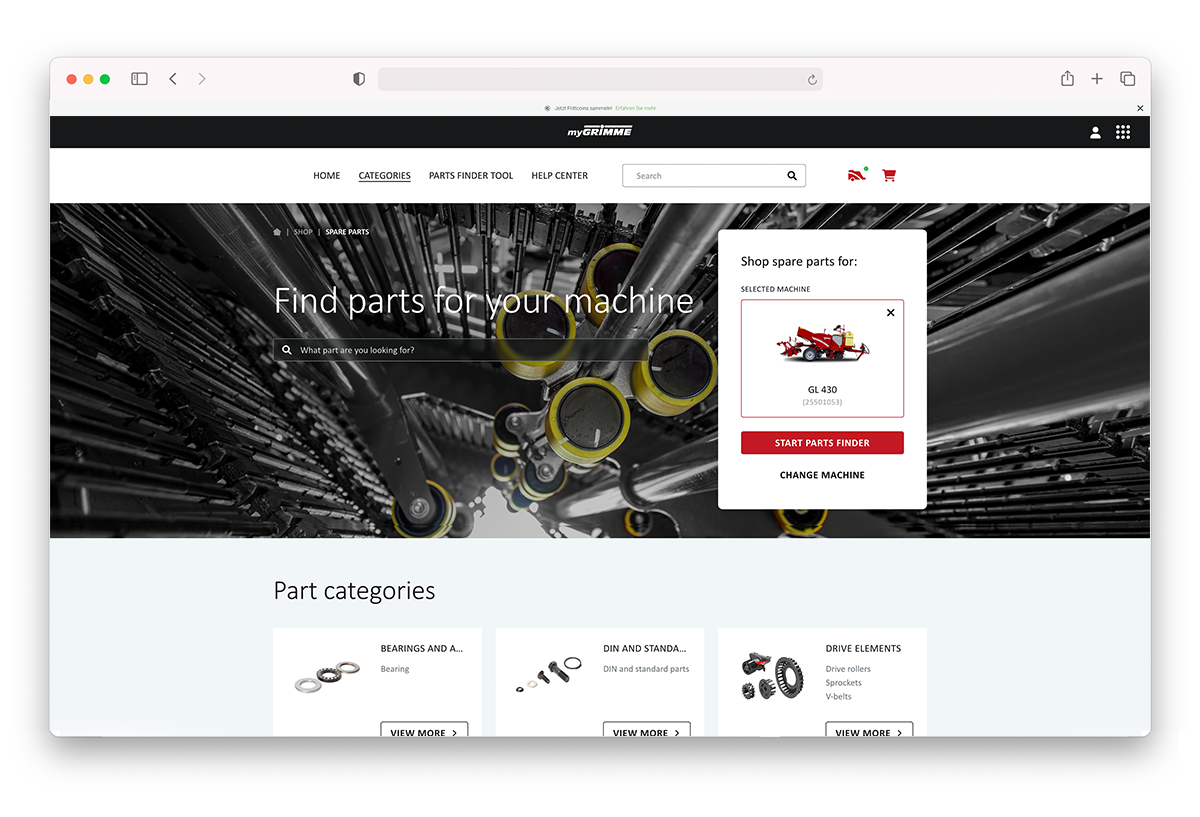

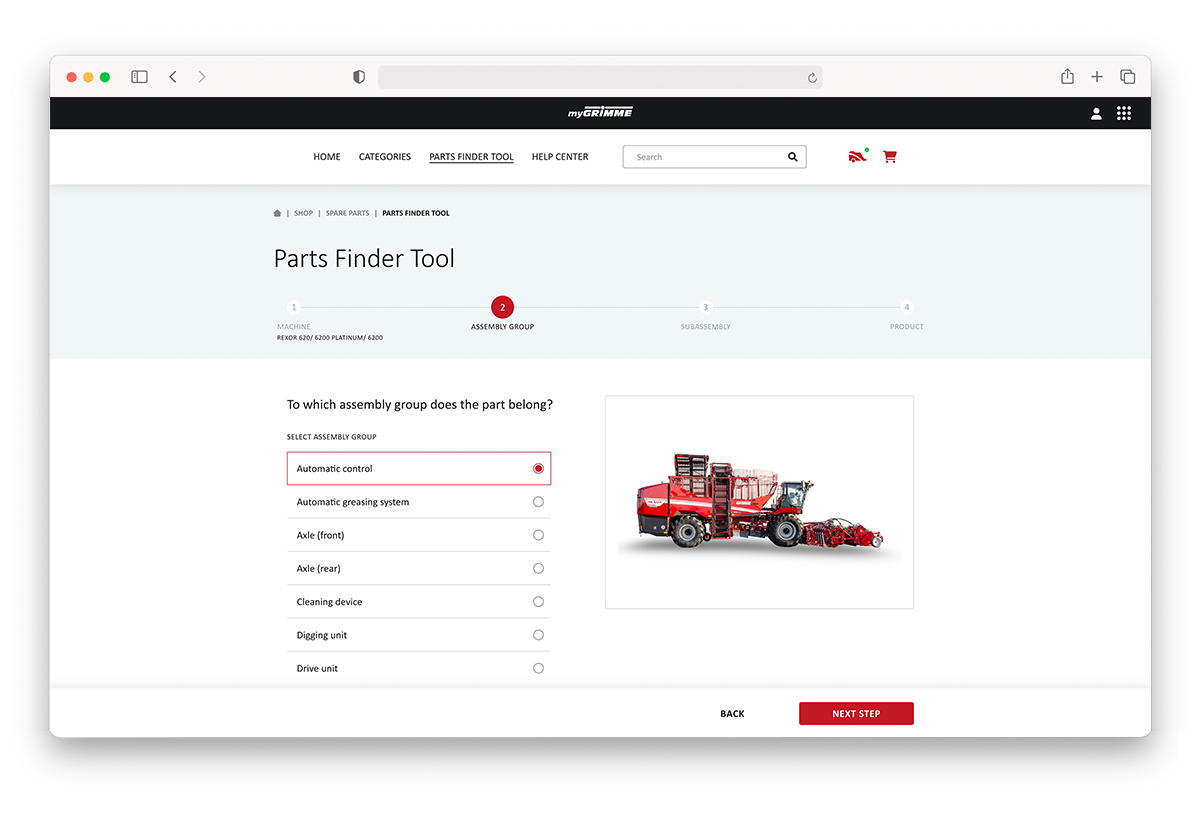

Development of the Spare Parts Finder

The custom-developed Spare Part Finder is the centerpiece of the new GRIMME Webshop, providing multiple ways for customers to locate the right parts for their machinery. The first step is to determine the machine requiring the spare part. The search can then be narrowed by selecting various assemblies and sub-assemblies until, in the fourth step, the part needed is found and can be added to the shopping cart. There are three entry points for using the Spare Part Finder:

- enter the machine’s serial number manually.

- identify the machine series based on selectable criteria such as vegetable technology, machine category, year of manufacture, and model.

- select the machine from the fleet stored in the user’s myGrimme account.

additionally, the entire shop can be filtered to display only parts of a specific machine, ensuring that customers only see relevant parts on all pages of the shop.

Single Sign-On

By setting up Single Sign-On (SSO) for the shop, customers with a myGRIMME account can log in using their existing credentials. Authentication is handled through a connection to Microsoft Azure. This integration allows the shop to access and utilize address data, contact information at GRIMME, and details about the customer’s machine fleet stored in myGRIMME.

Design customization

The front-end design of the Spryker shop has been customized to match the familiar GRIMME design seen in other GRIMME applications. This ensures a consistent look and feel, providing a seamless customer experience across all applications.

Click&Collect

The Click&Collect feature enables customers to order machine parts online and pick them up from one of four GRIMME depots in the UK.

Accounts & Admin Mode

In Spryker, customers can store addresses, shopping carts, and favorites in their accounts. The admin mode allows GRIMME service representatives to create and store shopping carts for registered customers within their accounts. This enables service representatives to locate spare parts and ensure their availability. Customers only need to check out the prepared shopping cart.

Discounts

Discounts are managed through the Spryker coupon module, where they are calculated and applied to the shopping cart. Discounts can be combined, allowing both basic and special discounts to be applied to certain product groups. Additionally, discount groups can be defined in Pimcore for specific product categories, and these can be automatically applied in Spryker.

Pimcore PIM

GRIMME Landmaschinen utilizes the Pimcore data management system as the central hub for managing and providing product and machine data, as well as images for the online shop and other applications. Pimcore is integrated with Spryker and the company’s ERP system. Data from the ERP system is imported into Pimcore. Additionally, manual data maintenance is possible. Machine data, product data, and categories are transferred from the Pimcore PIM to the Spryker shop. Product and machine images are provided to Spryker via an S3 bucket. Data from Pimcore is made available to other applications through API interfaces, enabling functionalities such as service checks. Pimcore is hosted by basecom at maxcluster. Currently, approximately 700,000 data objects and 27,000 assets are managed in Pimcore.

UX & UI

- Consulting in the field of UI and UX

- Assisted GRIMME’s internal UI/UX department

SEO & Analytics

- Consulting on tracking concept

- Supported GRIMME’s internal analytics department

Conclusion

We are thrilled to be part of this exciting project with GRIMME Landmaschinen. The flexible structures of Spryker and Pimcore allowed us to develop a highly customized solution. Together, we successfully overcame numerous challenges. We are proud of the result and look forward to continuing our collaboration with the GRIMME team and supporting the project in the future.

Impressions

With the new Spare Parts Finder, GRIMME customers can easily and reliably find the right spare parts for their agricultural machinery and order them online.

Company info

Established in 1861 and headquartered in Damme, Germany, GRIMME is a family-owned company renowned for its innovative and cost-effective solutions in potato, beet, and vegetable technology. As part of the GRIMME Group, which includes SPUDNIK (USA), ASA-LIFT (Denmark), INTERNORM (Damme), RICON (Rieste), Schmiede.One (Düsseldorf) and GRIMME itself, the company employs over 3,100 people worldwide and offers more than 150 machine models.

Christoph Jung, Director Business Unit

We look forward to getting to know you

Christoph Jung, Director Business Unit